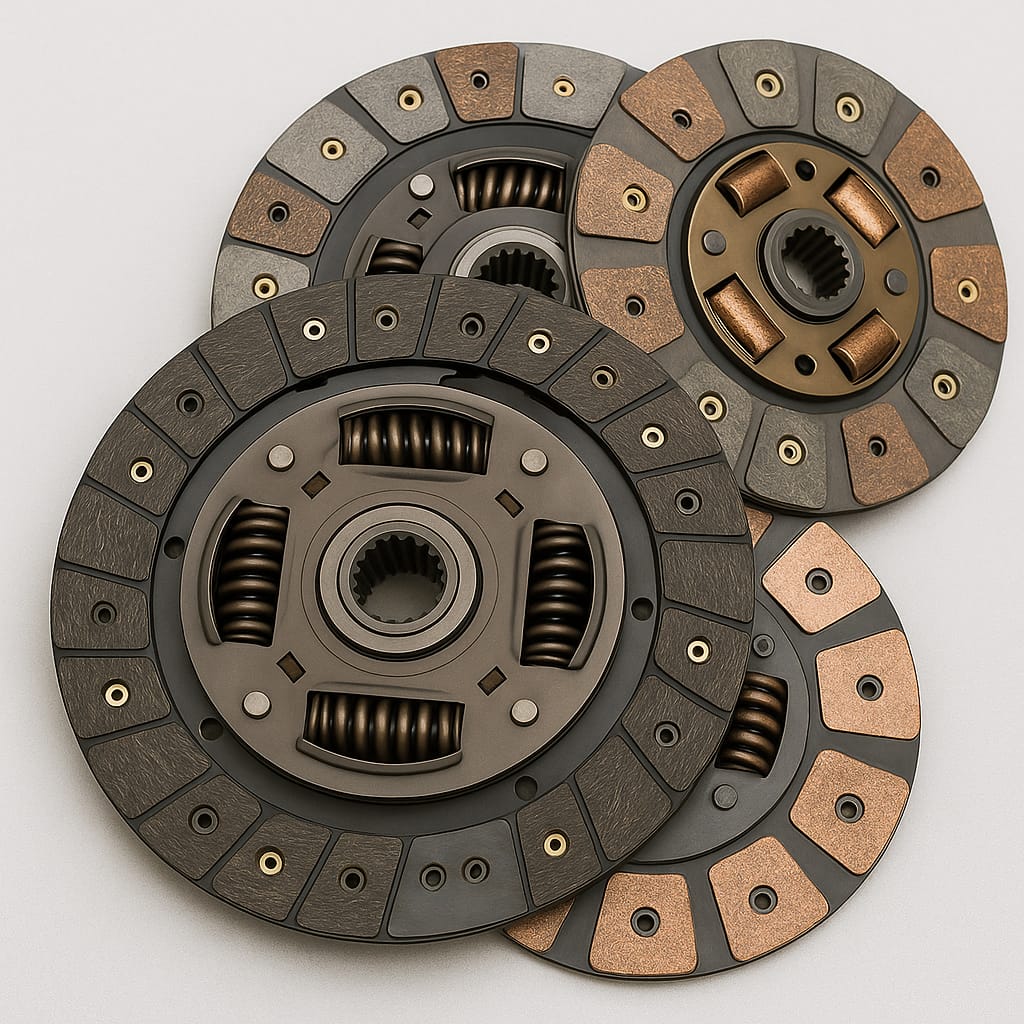

Types of clutch plate ( and material used in their facing)

Clutch is a essential part that links PTO (Power Take-Off) to the engine and gearbox. Understanding the different types of tractor clutches and their maintenance is essential for prolonging your tractor’s lifespan and enhancing its efficiency—whether you’re a new buyer or an experienced farmer looking to upgrade. Let’s explore the various classifications of tractor clutches.

Table of Contents

ToggleTypes of tractor Clutches Based on Operation

Single Clutch assembly

This simple clutch system runs one friction plate to control the PTO as well as the gearbox. It stops the tractor and implements at once. It is ideal for small-scale farming. The limitation of this clutch is that the PTO is limited while the clutch is pressed, therefore limiting operations. For example: the Swaraj 735 FE tractor has a single clutch.

Dual Clutch assembly

The dual-clutch can operate two clutch plates (transmission clutch and PTO clutch) with a 2-stage longer pedal that is utilised twice during gear changes—once to move to neutral and once to the intended gear. It is designed for heavy-duty implements like rotavators, harvesters, etc., needing exact control. Benefits include less gear grinding, less fuel consumption and help to synchronise gear speed. Swaraj 742 XT is one of the tractors using this clutch.

Double clutch assembly

There are two clutch plates in this system—one for tractor movement and another for PTO operations. There is a hand lever called IPTO (Independent Power Take-Off) for handling the PTO clutch and a foot pedal for controlling the transmission. Double clutch, like the one used in Mahindra yuvo tech+ 575 DI, is ideal for mid-sized to large-scale farms with several implement uses. PTO operates outside of the main gearbox and improves multitasking; hence, you can easily stop the implement without stopping the tractor.

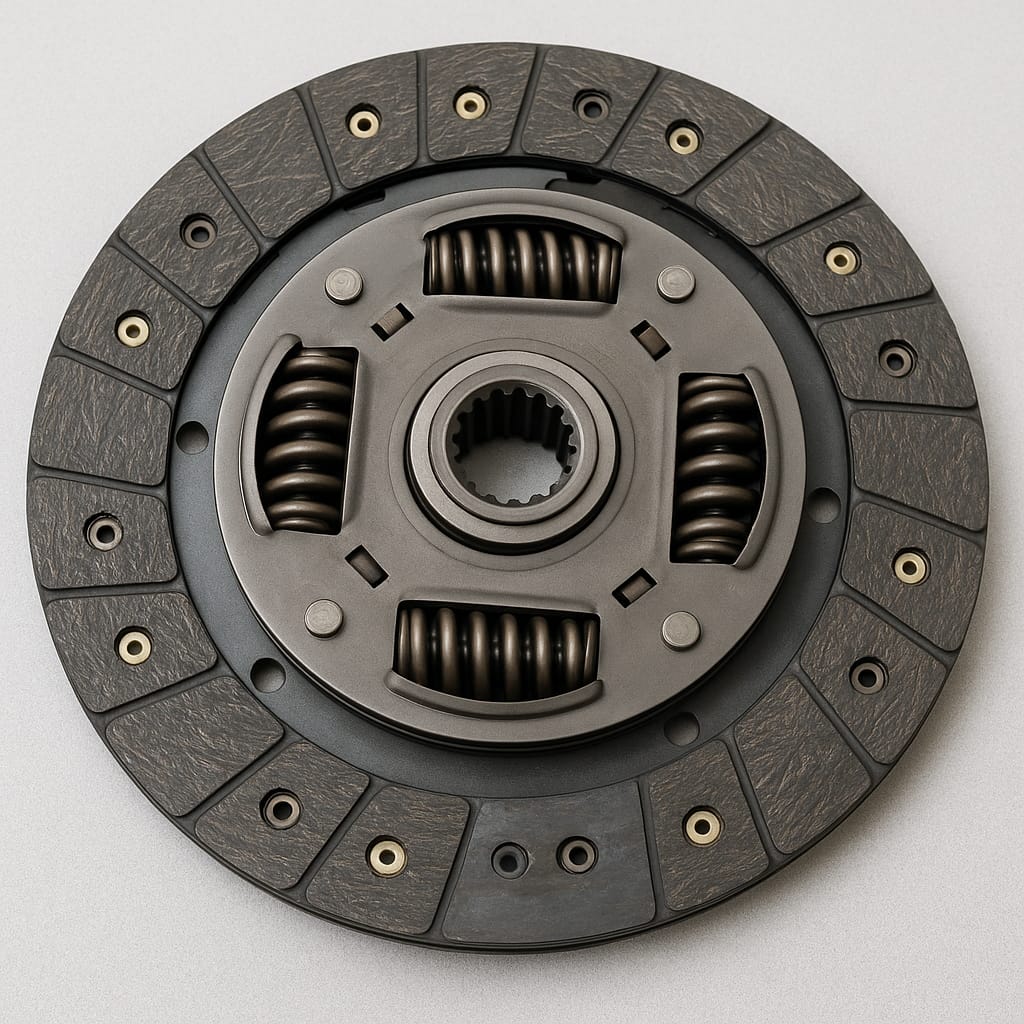

Types of clutch plate based on disk Facing

| Type | Temp. (°F) | Best Use | |

|---|---|---|---|

| Woven Organic | 600 | Daily Driver | |

| HD Organic | 700 | Most Street Performance, Towing, and Hauling Applications | |

| Ceramic | 1000 | Racing | |

| Feramic | 1000 | Racing/Agriculture | |

| Feramalloy | 1000 | Heavy Duty Hauling and Towing; Commercial Trucking | |

ORGANIC (White Facing)

Organic facings are typically made from phenolic resins, friction modifiers like metallic powder or metal oxides, and compounded rubber. These facings come in two types:

As you can see, woven organic facings are much stronger than molded facings, which translates to better life and performance.

Woven organic friction materials are commonly used in OEM applications, as they offer a good combination of smooth engagement, wear resistance, and strength.

Summery.

In almost all cases, woven is better than molded. For most vehicles, a woven organic clutch offers the best combination of performance, durability, drivability, and cost.

HEAVY-DUTY ORGANIC (White Facing)

Heavy-duty organic clutch facings are similar to normal organic clutches in terms of engagement smoothness, but with more temperature resistance and durability.

Heavy-duty organic clutch facings feature more metallic content, which boosts heat resistance and reduces fade.

This gives these clutches resistance to temperatures as high as 700°F, at least for short periods, as well as increased burst strength.

Summery

CERAMIC (Black Facing)

Ceramic clutch facings are composed of a blend of copper, iron, tin bronze, silicon dioxide, and/or graphite. The material is sintered or brazed onto a backing plate and often riveted to the main clutch plate.

These facings can endure high temperatures—up to 1,000°F—without fading, making them ideal for racing applications. However, it’s important to note that ceramic clutches typically have a high ratio of static to dynamic friction, which can result in more abrupt engagement.

FERAMIC

Feramic clutch facings, with their high coefficient of friction and high static-to-dynamic ratio, are primarily designed for racing applications where quick lock-up is paramount.

Composition and Design

These facings are constructed from a blend of steel, silicon dioxide, tin bronze, and graphite. Feramic facings can cover the entire clutch face (full-face) or be designed as smaller contact points (buttons).

Carbotic Facings

A specialized variation, known as a carbotic facing, is used in truck applications. This material provides ceramic-like temperature resistance while still allowing for smoother engagement than standard racing feramic.

FERAMALLOY FERAMIC

FeramAlloy facings are poised to replace traditional ceramic facings. They offer comparable wear and temperature resistance but feature a significantly improved static-to-dynamic ratio, resulting in smoother engagement and notably less chatter than ceramic materials.

conclusion

There Are 4 type of clutch plate (Disk) Used in tractor

Very low-quality white facing. organic material used

Low quality White Facing. organic material used but in high quality

Standard Quality Black Facing. mix material use like

High quality Black facing. material used like copper, iron ,tin bronze, silicon, or graphite