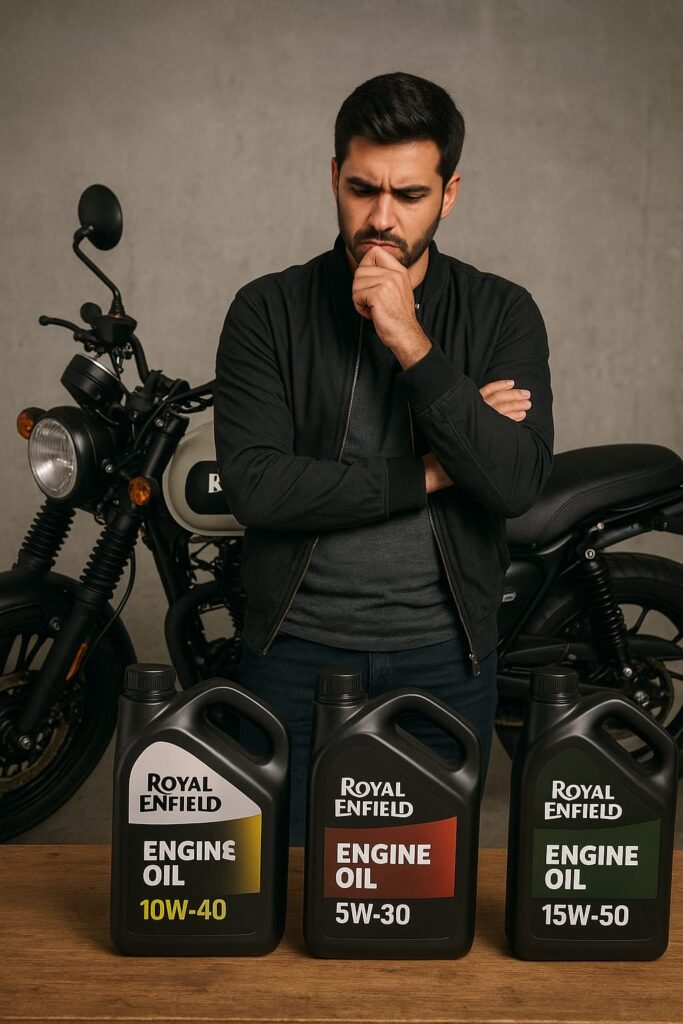

Which Mobil is best for my bike

Which engine oil is best for a bike—

mineral (conventional)

Fully synthetic

Semi-synthetic

This question arises in the mind of almost every rider. The job of engine oil is not just to reduce friction but also to keep the engine cool, clean, and prolong its life. For this reason, choosing the right oil becomes important.

Table of Contents

ToggleLet us understand these three types in simple terms.

Mineral or conventional oil is made by refining base oil. It is the most economical option and proves adequate for everyday normal riding.

However, its performance may be limited in high temperatures, high revs or prolonged hard driving. Due to its comparatively lower oxidation resistance and deposit control, it needs to be changed relatively frequently.

Fully synthetic oil is chemically engineered, making its molecules more uniform and stable. As a result, it provides better protection in both extreme heat and cold, flows faster during cold starts, maintains film strength at high revs, and generally contributes to better mileage and engine longevity.

It is usually expensive, but in many cases can extend drain intervals, provided the manufacturer’s recommendations are followed.

Semi-synthetic oil is a blend of mineral and synthetic oils. Its cost and performance lie in the middle—better thermal stability and cleanliness than mineral oil, but not as high performing as full synthetic. For daily office commutes, moderate distances and normal riding, it is considered a balanced choice, especially if you do not want to spend entirely on full synthetic but desire better protection than mineral. So, which should you choose?

First, check your bike’s owner manual—it clearly states the viscosity grade (such as 10W-30, 10W-40), API/ACEA and JASO (such as JASO MA/MA2)

specifications. Engine CC, your riding style (city traffic vs highway), weather/temperature, service intervals, and warranty conditions also matter. For general use, semi-synthetic is often sufficient.

full synthetic can be beneficial for performance riding, extreme temperatures, or long highway rides. Only go for unnecessarily expensive oils if needed and approved by the manufacturer. If in doubt, consult the brand’s customer care or an authorized service center—and yes, let us know which oil you use in your bike!